|

Cyclone

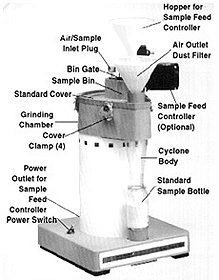

Sample Mill - DIRECT DRIVE - MODEL 3010-014 General Description:

*Patent No. 3,754,715 |

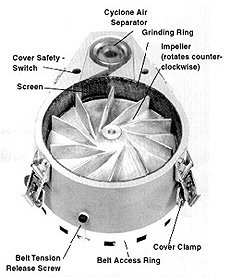

| UDY Cyclone Sample Mills use a patented* method of grinding. The grinding chamber is illustrated in Figure 2. High speed rotation of the impeller and air currents throw particles into, and rolls them around the grinding ring. Particles remain in the grinding chamber until impact-shattering and abrasion make them small enough to flow out the exit with the air current. The air flow removes essentially all material and makes clean out unnecessary. The air flow also minimizes heating and therefore eliminates thermal degradation. | |